Project Info

Project Description

ltra High Performance Concrete (UHPC)/ Ductal Concrete is the perfect material for the restoration of heritage buildings and structures. Szolyd Development utilized UHPC in the recent restoration of Pioneer Courthouse Square in Portland Oregon, the outcome is both aesthetically authentic and structurally superior.

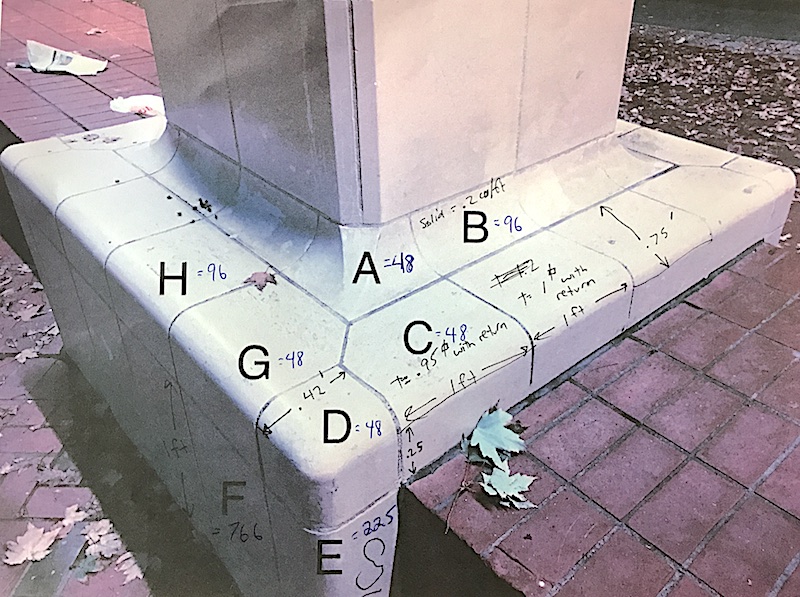

Szolyd Development utilized Ductal/UHPC concrete for the restoration of the Stoa column bases for Pioneer Courthouse Square located in downtown Portland, Oregon. 1500 masonry blocks of ductal concrete were manufactured to replace the 30 year old glazed terra cotta bases.

Pioneer Courthouse Square is a high traffic and high profile monument and considered the “heart of Portland”. The original terra cotta tiles have significantly deteriorated. Due to the deterioration, the city invested in the restoration of this important space. Ductal Concrete was chosen by the restoration team as the perfect material to reproduce the original aesthetic qualities, while providing a more robust, functional wear surface.

Emily Dawson of SRG Architects and Pioneer Waterproofing contacted the Szolyd team to begin the process of vetting Ductal Concrete for the application. After months of research and development, Ductal Concrete was specified by SRG. Multiple samples were created to reproduce the colour, texture, and glaze of the original terra cotta masonry units. The UHPC pieces were integrally coloured instead of topically coated, to better withstand wear and tear while maintaining form and aesthetic. The applied texture was part of a 3 tiered approach to the overall appearance (high build | etching | sanding).

During the demolition stages of the Stoa column bases, Szolyd requested a sample of each of the original terra cotta blocks to serve as masters for the urethane molds. This method was chosen to optimize time constraints. Another, more precise method, would be to mill new forms from digital files to create more geometrically true pieces. Terra cotta shrinks during the kiln drying process, therefore each block needed truing. The original blocks had been painted many times in an attempt to hide impact damage easily caused to such a soft material. In order to begin the molding process, all blocks had to be stripped to the raw terra cotta.

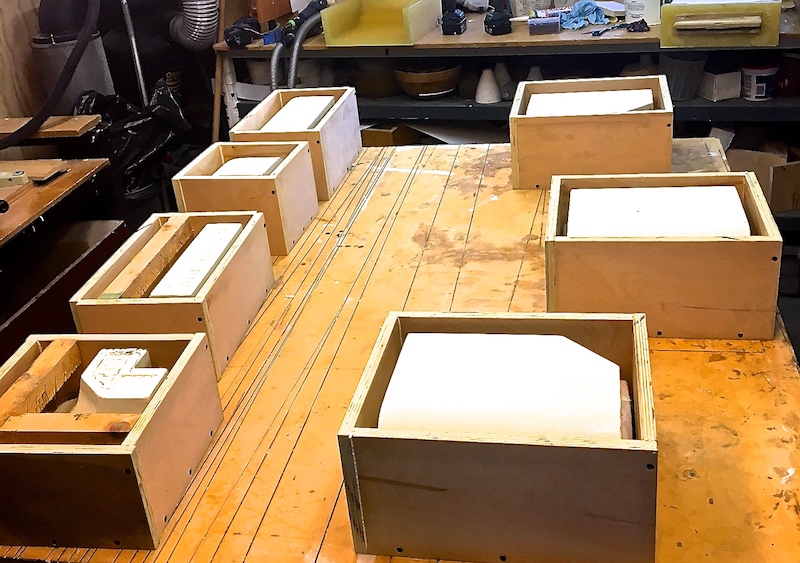

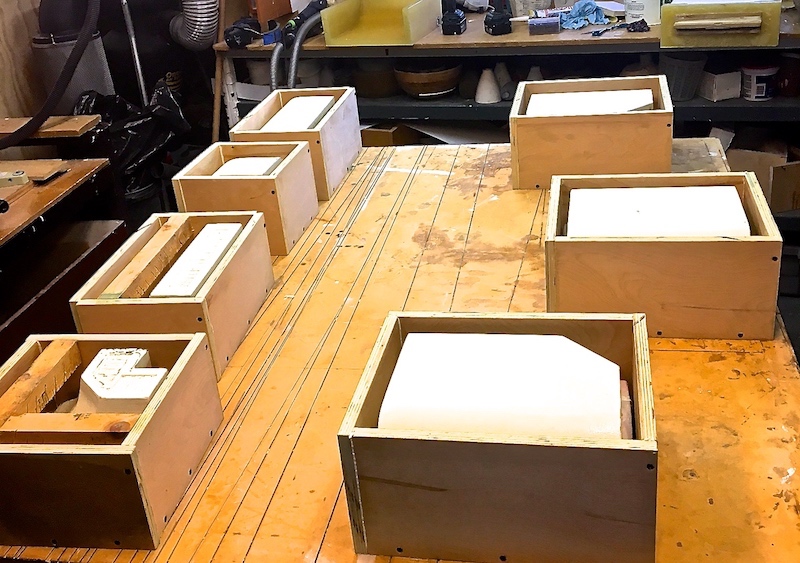

There were 8 different types of blocks, with varying quantities needed of each. The molds were designed to last for the duration of the project.

Smooth-On PMC 780 rubber was used in order to optimize mold durability and flexibility for ease of release. Approximately 100 molds were created for a total of 1500 Ductal blocks.

This completed Phase one of the restoration of Pioneer Courthouse Square, Szolyd was honoured to be part of the revitalization of the heart of Portland.

https://www.srgpartnership.com/ideas/essays/ultra-high-performing-living-room