Ductal color

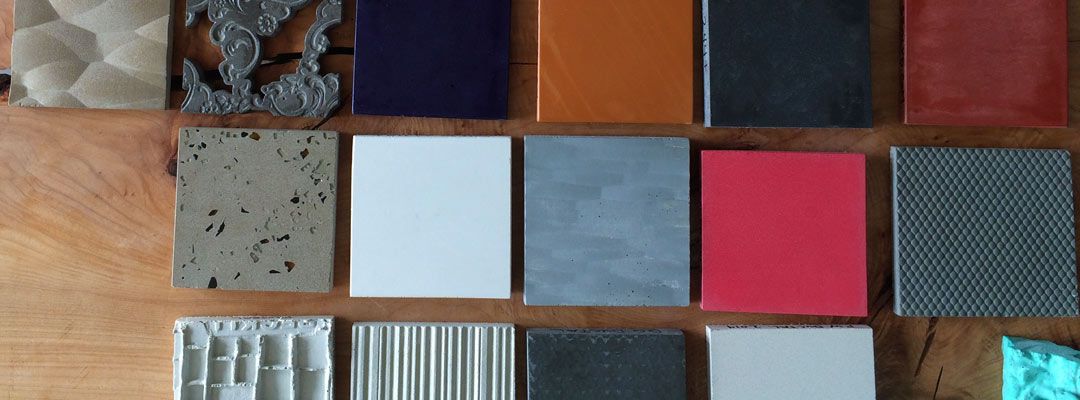

Ductal is produced as either a white or gray powder and can be integrally colored in a wide range of shades. Castings are striking in the visual uniformity of their coloration. Rigorous quality control, watertight molds that prevent leaching, and a fluid mixture that does not segregate or form bug holes, flow lines or segregation can make the concrete remarkably free from mottling. Interesting effects can also be produced by swirling together different colors; the rheological characteristics of Ductal enable the colors to mix without blending, as would happen with ordinary concrete mixtures.

Integral color

Liquid and powder integral pigments are added to the batch to create colorfast, UV stable concrete products. A wide range of colors with a uniform shade are possible.

Color stability

Extremely low porosity and permeability means that colors are far more stable than with conventional concrete.

Batch consistency

Quality control measures taken by the largest concrete manufacturer in the world mean that color is consistent from batch to batch.

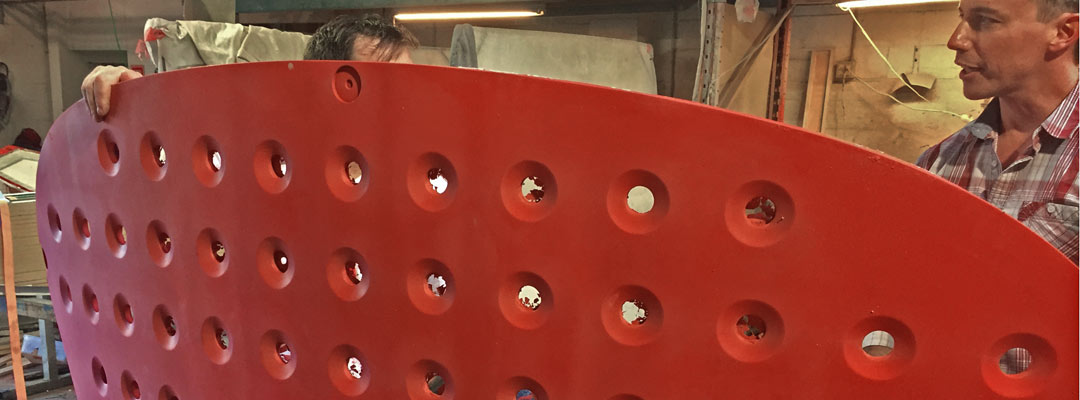

Bright red concrete

Bright red concrete Iron oxide

Iron oxide Vibrant impact

Vibrant impact Sky's the limit

Sky's the limit Custom samples

Custom samples Corten steel? No - colored concrete

Corten steel? No - colored concrete Shades of grey

Shades of grey