Project Info

Project Description

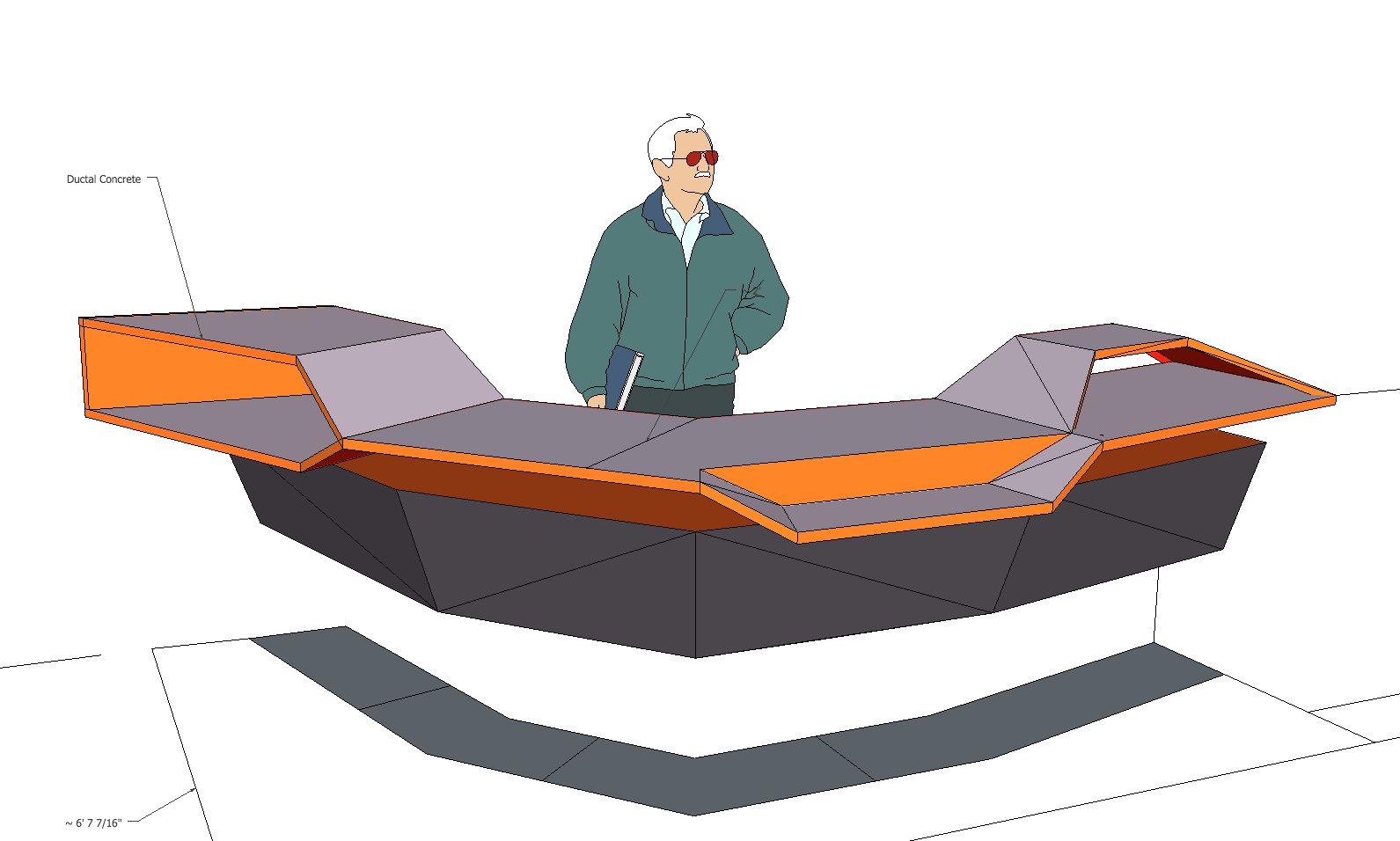

hen the new Crag X gym was proposed, owners Nikolai Galadza and Kenneth Cronin had a grand vision for the space. With the angular faceted design and industrial concrete construction the reception desk had to be something special.

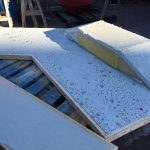

The mold build was a complicated undertaking requiring some creative thinking. Light grey UHPC Ductal concrete was cast at 1″ thickness into 4 different molds designed to fit together with precision. Fasteners were embedded to fix the pieces with respect to each other and to the cabinetry.

The designer, Grant MacPherson, created mdf positives of each component out of 1″ material. The Szolyd team utilized the positives as the framework and negative wood molds were built around each unit.

In order to create the desired sharp angular shapes the inner mold parts were constructed out of a softer material. Urethane rubber was poured into the waxed mdf cavities creating a perfect inner mold component.

The UHPC Ductal concrete was cured for two days and then the back of the casting was diamond ground flush. The outer mold parts were removed, leaving the tricky rubber inner molds. Compressed air and shims aided in the delicate process of removing these inner rubber components.

The final product is the result of clever design and sophisticated mold building. It showcases UHPC Ductal’s inherent properties to allow thin section, cantilevered casts, and architectural finishes.