Benefits of UHPC (ultra high performance concrete) for Site Furnishings

UHPC (ultra high performance concrete) is a game changer when pertaining to Site Furnishings and exterior products. Simply put, it is concrete on steroids.

The material’s combination of superior properties facilitates the ability

to design thin, complex shapes, curvatures and highly customized textures – applications which are difficult or impossible to achieve with traditional reinforced concrete elements.

Structural Properties of UHPC

UHPC is structurally more comparable to steel than traditional concrete. As a result, far less than 70% of the material is needed to achieve the same structural requirements. This leads to much lower weight, not because of the density of material but as a result of a thinner profile. These slim castings require less substructure and smaller foundations, thereby reducing infrastructure costs and environmental impact.

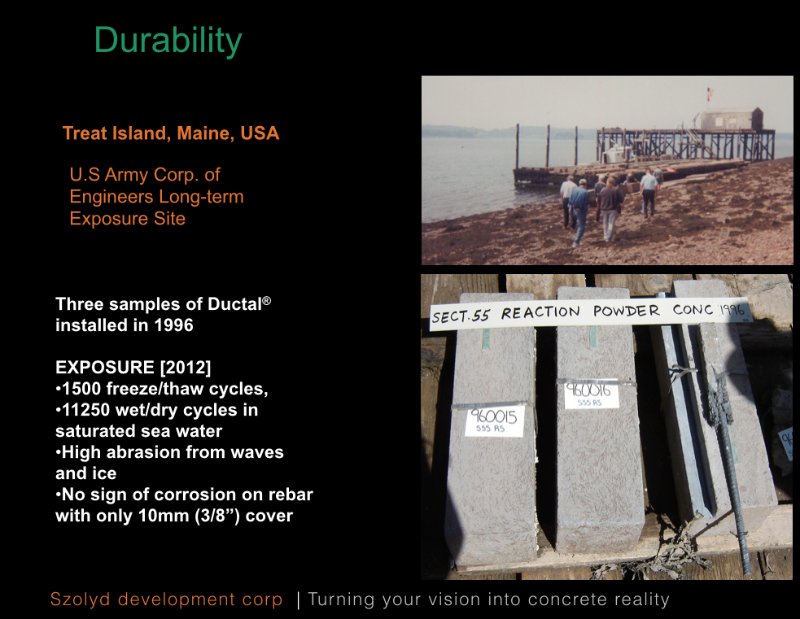

Durability Properties of UHPC

UHPC does not contain the capillary pores of traditional precast or glass-reinforced concrete. This means that it does not absorb water and degrade in demanding freeze-thaw or marine conditions. Its increased density and decreased porosity result in a material that is extremely resistant to acid chloride and sulphate penetration. UHPC also demonstrates extreme resistance to freeze-thaw cycles, abrasion, and other aggressive environments.

UHPC products will look better for longer, and have a enhanced service life.

Surface Quality Properties of UHPC

UHPC is a SCC mix (self consolidating concrete). It flows into complex forms extremely well and has greatly reduced air bubbles and imperfections in the surface. The combination of a low slump material, lack of large aggregate, and minimal air entrainment, result in a product that that casts nearly flawlessly.

Along with the lack of passive reinforcement, UHPC’s ability to self-consolidate allows for production of complex shapes and geometry, thin cross sections, and lattice effects (in some cases up to 75% of the material can be eliminated). With advancements in CNC machining and rapid prototyping, any shape that can be imagined or designed with 3d software can be cast in concrete.

Mainstream Acceptance of UHPC and concrete based products.

There is a major influx of concrete based products emerging into the market. Not all of them are UHPC, but it demonstrates the markets desire and acceptance of these products. UHPC is a modern day marble. Products and projects manufactured with this material may be around for as long as some of our historic monuments and one day be ancient artifacts in museums.

Designers such as Frank Gehry, Zaha Hadid and Rudy Ricciotti are utilizing UHPC to create building facades, stair features and unique products. We are just starting to see what is possible with this wonderful material. Let the dreaming begin……..

Here is a list of a few companies doing unique work with UHPC

Il Cantiere – http://www.ilcantieresrl.it

Il Cantiere is an Italian based company who are at the forefront of the UHPC movement. They manufacture tables, shelving and all kinds of interior and exterior based products.

Mend Restoration – http://mendrestoration.com

Mend Restoration is utilizing ductal to replace damaged terra cotta building components. Terra buildings are in an abundance in North America and many are in a serious state of disrepair. There are only a couple terra cotta manufacturers left in North America, and it is an extremely expensive and time consuming process. UHCP is proving to be a great alternative to replacing damaged components, or replicating entire facades.

Escofet – http://www.escofet.com

Escofet are the international leaders with UHPC concrete and site furnishings. They have been in existence for 125 years, and have an extensive history with precast concrete and mould design. Antoni Gaudí’ designed products for them as far back as 1904. Today Escort is bringing very progressive designs to the forefront of the design world.

Szolyd Development – https://www.szolyd.com

Szolyd is a BC based UHPC manufacturer with an extensive track record for pushing the limits of UHPC. Szolyd has teamed up with many artists to utilize UHPC for unique art installations, which has been the basis of its research and development. Recently, Szolyd has joined forces with Landscape Furnishings to develop a line of site furnishings.

reet rutru